Fremantle Port Authority (FPA)’s Kwinana Bulk Cargo Jetty (KBJ) Conveyor CV05 was installed circa 2003 and consists of a head end drive and discharge pulley with vertical festoon gravity take up delivering fertiliser from CV03 to CV06. The conveyor has generally been operating satisfactorily. The tail pulley has previously been installed with diamond pattern rubber lagging and recently there had been preferential lagging wear on the outside approximately 200mm wide from the shell edge on both sides.

The scope of this design review report is to perform a high level mechanical conveyor calculations to compare the existing conveyor equipment (drives, belting, pulleys, idlers and take up) selection and set outs (transitions, loading point and vertical curves) with requirements from the calculations. Recommendations of any modifications or further investigations required for satisfactory operations of the conveyor are provided as conclusion in this report.

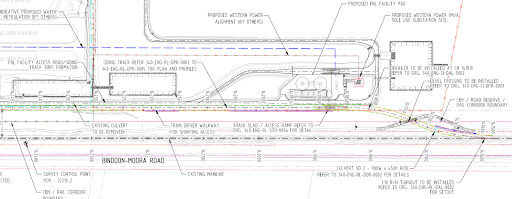

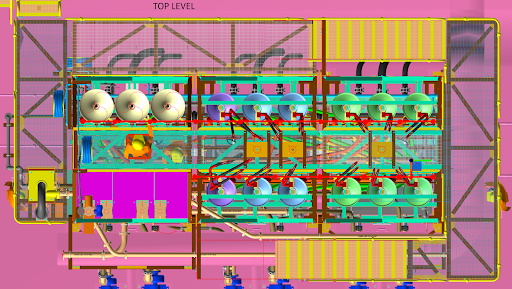

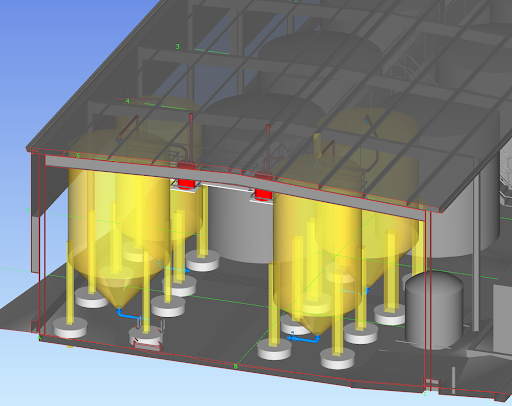

BNV conducted site inspection of tail pulley wear & performed conveyor calculations for recommendation to improve conveyor tail end transition. Upon client acceptance of the solution, BNV performed 3D scanning survey & delivered detailed design fabrication drawings for the brownfield modifications.

CBH Group – Independent Design Verifications

Location & Year

Kwinana Bulk Cargo Jetty (KBJ), Kwinana, Western Australia – 2022

Client

Fremantle Port Authority (FPA)

More Projects